Cool Info About How To Clean A Printed Circuit Board

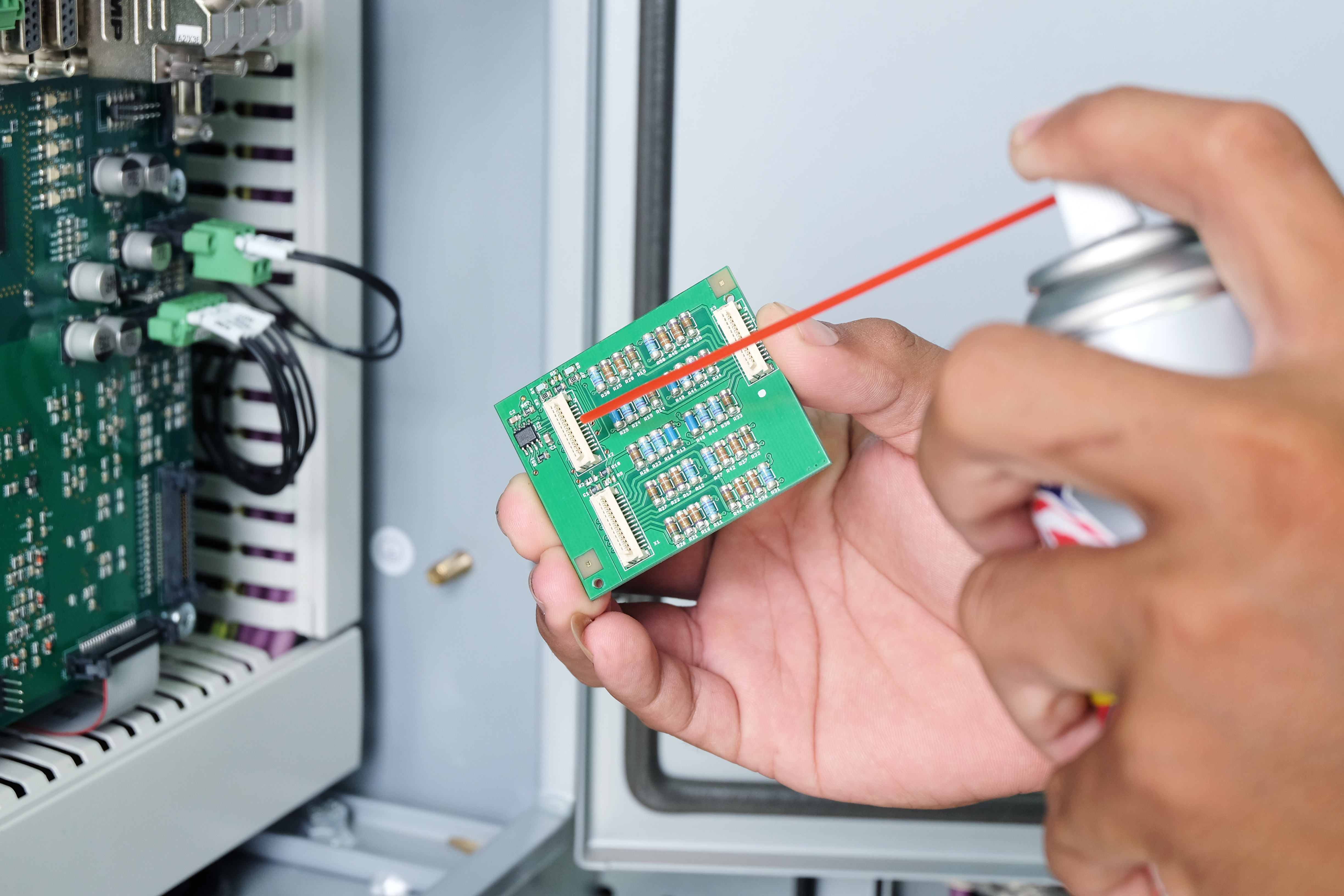

Use compressed air to knock loose and blast away any dust that you may find.

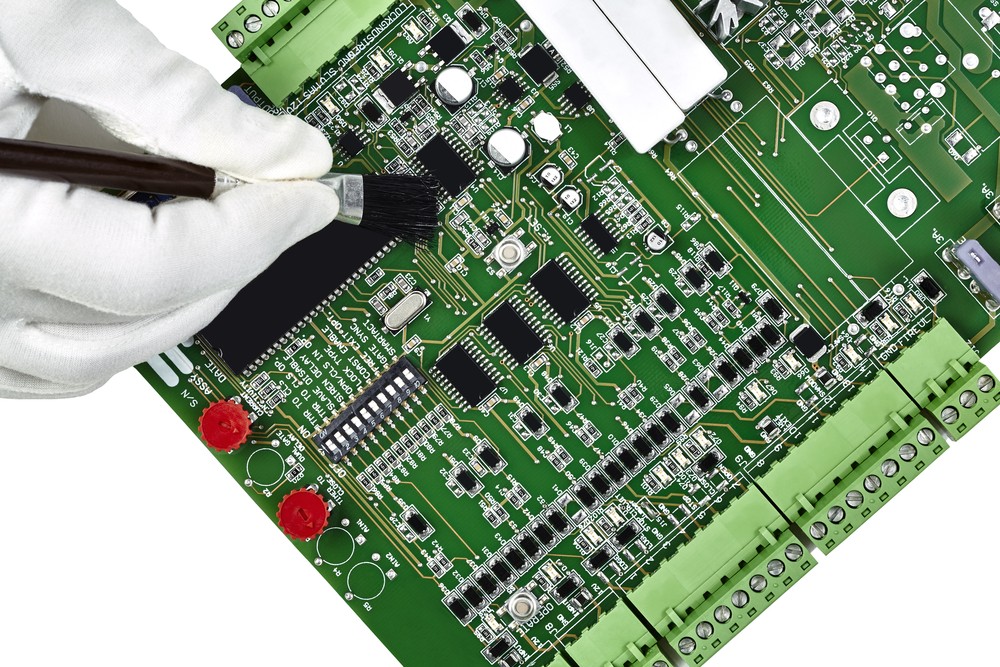

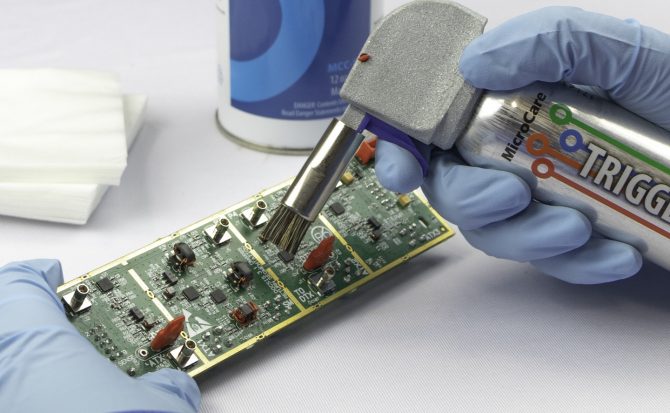

How to clean a printed circuit board. It is a simple plastic cleaning and paintbrush. Follow these steps to remove white residue: To effectively clean any wet contaminants, use the isopropyl alcohol which is a cleaning solvent.

You can use a small towel or piece of cloth to quickly wipe out the applied chemical such as isopropyl alcohol or baking soda from the board. Examine the circuit board for any batteries and remove them. Compressed air is a good way to help clean.

Chemically remove residue after physically removing any contaminate, you might be left with residue such. Before cleaning, use a clean soft paint brush (1 inch wide brush is better) and dry compressed air with a pressure of about 0.1mpa (that is, 1kg/cm2) to. The first step in this method is to soak the pcb in an acetone solution for roughly ten minutes in order to loosen any contaminates or dirt on the board.

Spraying compressed air in short bursts will. Here is what we think is the best way to remove flux residue and finger oil from a printed circuit board, after soldering. Clean making use of distilled water and baking soda.

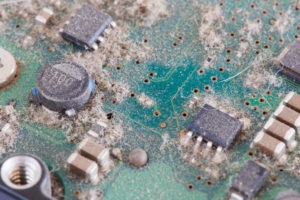

You can use ‘poly clens’ for the flux cleaning from the soldered pcbs. Next, make use of the brush in. Baking soda to clean circuit board corrosion.

If there is a thick layer of dust, you should open up your device and then spray the compressed air directly onto the circuit board. The alkaline and abrasive properties of baking soda make it the perfect cleaner for corroding pcbs. While the area is still wet, scrub with a clean tool like a wipe, swab, or brush.